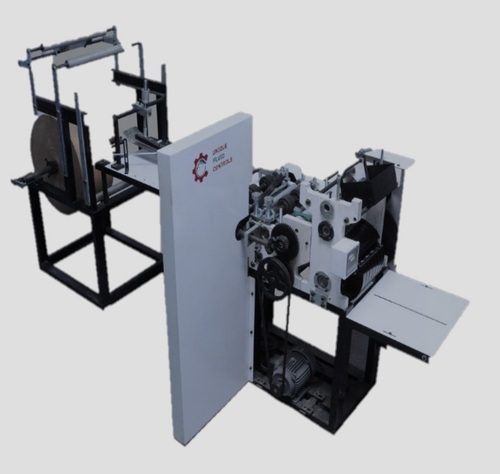

Medicine Cover Making Machine

Price 325000.0 INR/ Watt

MOQ : 1 Watt

Medicine Cover Making Machine Specification

- Grade

- Industrial

- Type

- Automatic

- Material

- Mild Steel & Aluminum

- Capacity

- 5000 covers per hour

- Computerized

- Yes

- Control System

- PLC Controlled

- Cutting Speed

- 50-100 pieces per minute

- Cutting Size

- 150 mm x 250 mm (adjustable)

- Cutting Thickness

- 10-50 microns

- Voltage

- 220 V / 50 Hz

- Power

- 2.2 kW

- Weight (kg)

- 900 kg

- Dimension (L*W*H)

- 3500 mm x 1400 mm x 1700 mm

- Color

- Blue & Silver

- Motor Type

- Servo Motor

- Display

- Touchscreen HMI

- Noise Level

- 70 dB

- Feeding System

- Automatic Roll Feeding

- Air Pressure Required

- 6 Bar

- Bag Type

- Flat Medicine Cover

- Film Material Supported

- Plastic, Paper

- Heating Method

- Impulse Sealing

Medicine Cover Making Machine Trade Information

- Minimum Order Quantity

- 1 Watt

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 30 - 45 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

About Medicine Cover Making Machine

Unique India paper texnix is manufacturing a Medicine cover making machine in coimbatore. We are supply the machines all over india. It is fully automatic paper cup making machine.Advanced Automatic Feeding and Sealing

Designed for seamless integration, the machine features an automatic roll feeding system and impulse sealing technology, ensuring consistent quality and efficient operation. Its servo motor enhances precision, while the PLC-controlled process and touchscreen HMI provide user-friendly control and monitoring.

Flexible Film Material Support

The machine accommodates both plastic and paper films, offering versatility for different packaging requirements. Adjustable settings allow for customized cover dimensions, making it suitable for a range of pharmaceutical packaging needs and increasing operational adaptability.

High-Speed Production Capability

Engineered to maximize output, the machine cuts at speeds between 50-100 pieces per minute and supports a capacity of up to 5000 covers per hour. This high throughput makes it ideal for large-scale manufacturers seeking efficiency without compromising quality.

FAQ's of Medicine Cover Making Machine:

Q: How does the automatic roll feeding system work on this medicine cover making machine?

A: The machine uses an automated roll feeding mechanism to supply plastic or paper film continuously into the forming section, minimizing manual intervention and ensuring a steady workflow. This increases productivity and reduces downtime.Q: What types of film materials are supported by the machine?

A: The machine supports plastic and paper films, allowing manufacturers to switch between material types based on their packaging requirements. Adjustable settings accommodate material thicknesses from 10 to 50 microns.Q: When is impulse sealing used during the manufacturing process?

A: Impulse sealing is applied during the cover formation phase to securely seal the edges of each medicine cover. The heating method uses short, controlled bursts for reliable seals suitable for pharmaceutical packaging.Q: Where is the display interface located and how is it used?

A: The touchscreen HMI (Human Machine Interface) is mounted on the front console of the machine, offering intuitive access to control settings, real-time monitoring, and operational adjustments through a user-friendly graphical interface.Q: What is the process for adjusting cutting size and thickness?

A: Users can customize cutting size and thickness via the touchscreen HMI, which interfaces with the PLC control system. The adjustment range accommodates cover dimensions from 150 mm x 250 mm and thicknesses from 10 to 50 microns.Q: What are the benefits of using a servo motor and computerized PLC control in this machine?

A: The inclusion of a servo motor and PLC control system delivers precise, repeatable motion and accurate automation. This results in consistent product quality, reduced operator error, and streamlined production.Q: How does the machine contribute to increased output and lower noise levels?

A: With a capacity to produce up to 5000 covers per hour and quiet operation below 70 dB, the machine supports high-volume production in industrial settings while maintaining a comfortable working environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

UNIQUE INDIA PAPER TEKNIX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry